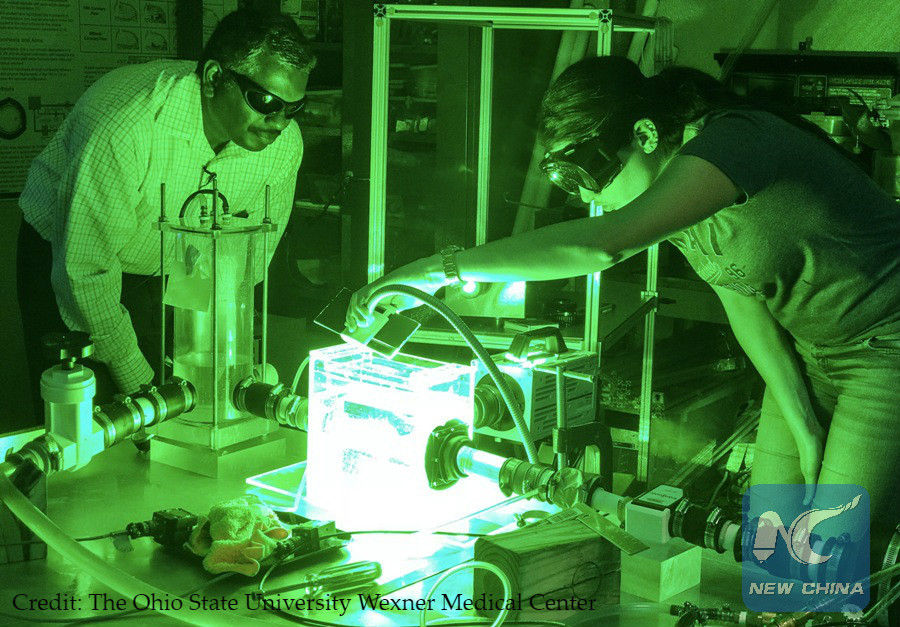

Prasad Dasi, PhD (left) of The Ohio State University College of Engineering tests a 3D-printed aorta in a high-tech simulator that replicates what happens in a specific patient's heart. The experiments allow experts to test different aortic valve replacement options to help doctors prevent complications in the operating room. (Credit: The Ohio State University Wexner Medical Center)

WASHINGTON, March 5 (Xinhua) -- American physicians are using innovative, three dimensional models to improve care for patients receiving aortic valve replacements.

A paper released on Monday in the ongoing annual CRT conference in Washington has shown that researchers have developed a way to model and predict potential complications so they can be avoided.

Patients' aortic valve needs to be replaced because their valve openings have narrowed. Usually, there are two options to replace the diseased valve: open heart surgery through a traditional opening of the chest, or a less invasive transcatheter method that deploys a tissue valve through a blood vessel in the leg.

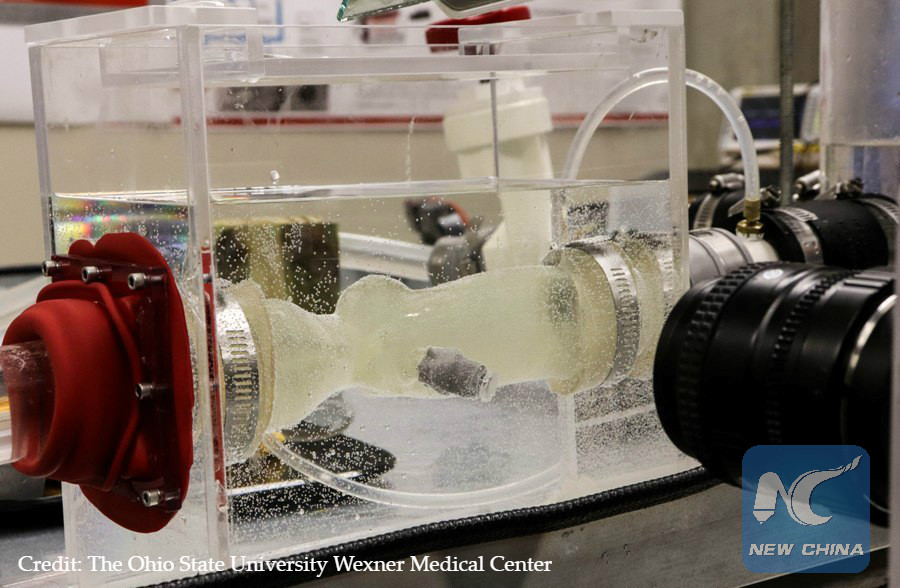

A 3D-printed replica of a patient's aorta is tested in a high-tech heart simulator. The experiment can test different heart valve types and positions to find what will work best for the patient and prevent complications. (Credit: The Ohio State University Wexner Medical Center)

To determine which way is better, they create personalized 3D models of the aortic valve and neighboring structures and simulate how the new valve will function.

"For most patients, available valves work comparably. However, in some cases the anatomy of the patient may create additional considerations. For example, the patient may have calcified nodules on the valve leaflets, or coronary arteries that arise in close proximity to the valve," said Scott Lilly, interventional cardiologist and co-director of the structural heart program at Ohio State Ross Heart Hospital.

Bernice Belcher, 78, takes her blood pressure daily along with diet and exercise to stay heart healthy. 3-D modeling of her heart structure guided doctors at The Ohio State University Wexner Medical Center to perform open heart surgery to replace her aortic valve, rather than using a transcatheter method. (Credit: The Ohio State University Wexner Medical Center)

Researchers precisely reconstruct a patient's aorta and 3D-print it from the patient's CT scan using various flexible materials that mimic the real aorta. They load the model into a heart simulator which pumps transparent, simulated blood through the system.

"Using laser and high-speed camera, we can measure blood flow velocity and vortex patterns with and without a replacement valve. We can model various therapies, positions and types of valves to better understand problems such as leakage, clotting or coronary obstruction," said Lakshmi Prasad Dasi from Ohio State's Davis Heart and Lung Research Institute.

Dr. Scott Lilly performs transcatheter aortic valve replacement at The Ohio State University Wexner Medical Center. A unique collaboration with biomedical engineers at The Ohio State University College of Engineering helps him choose the best option for each patient using a customized 3D model to test various options before valve replacement. (Credit: The Ohio State University Wexner Medical Center)

"We can observe how different valves not only relieve the stenosis but also minimize the likelihood of blood clots forming on the leaflets, which is the goal of the treatment," Dasi said.

"Each valve is a little different, and the anatomy of every patient is unique. The ability to predict the function of the valve after placement, and which valve may work best with the least amount of leak and without impinging on adjacent structures is critical," Lilly said.